Login

NEW CUSTOMERS

By creating an account with our store, you will be able to move through the checkout process faster, store multiple shipping addresses, view and track your orders in your account and more.

CREATE AN ACCOUNTSEARCH

Shopping cart

Lithos chyte

— the Greeks called glass molten stone.

Multifaceted Craftsmanship

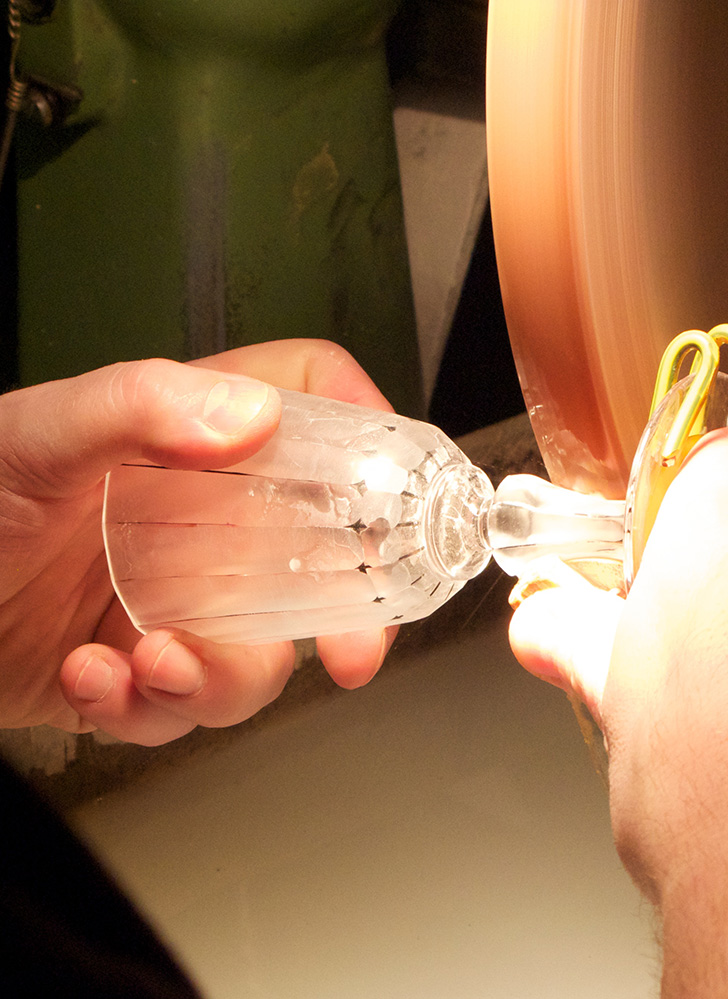

When grinding a glass to create its shape, a large amount of glass is removed from the hand-blown blank. The base of each glass is ground flat, and the blanks—always round—are squared and adorned to the designed shape with faceting and ornamentation. Is it also during the cutting process that the reflection of light by the crystal is fine-tuned. Our specialised craftspeople gently press the piece being worked against rotating stone discs of various shapes and grains, a process which requires tremendous skill, intuition, and visual acumen. Water is used to keep the frictional heat of sanding to a minimum and to wash the sand away. Often, as many as 15 different discs are needed to create all the arcs and details of the design in a single glass. At Lobmeyr, our principle is to adapt the tool to the design, not the design to the tool, a tenet which is sometimes reflected in the price.

At Lobmeyr, we see glass either as a solid fabricated stone, carefully shaped through the cutting process, or as a delicately blown material — as light as a bubble.

Cutting is one of the most important glass finishing techniques there is. Only once cut does a glass blank blown by a master become, for example, a finely faceted drinking glass reflecting the candlelight on the beautifully laid table a thousand times over. Our glassware is cut in the Lobmeyr workshop in Vienna, with traditional craftsmanship that allows each glass to become a treasure.

Sparkle

The deciding factor is the polish. Sanding creates a matte surface that subsequently needs to be polished to regain its transparency and shine. Industrial acid polish, common in today’s mass glass production, is never used at Lobmeyr, as it dissolves the exquisite precision of the manual cutting process. We use the traditional technique instead, with each piece being polished in three steps using rotating felt and cork discs. This is the only way to achieve a result that satisfies our high standards: An inimitable, natural shine.

STORIES

STORIES